This model is no longer in production and is unavailable for purchase. Please browse our catalog to explore the latest available models.

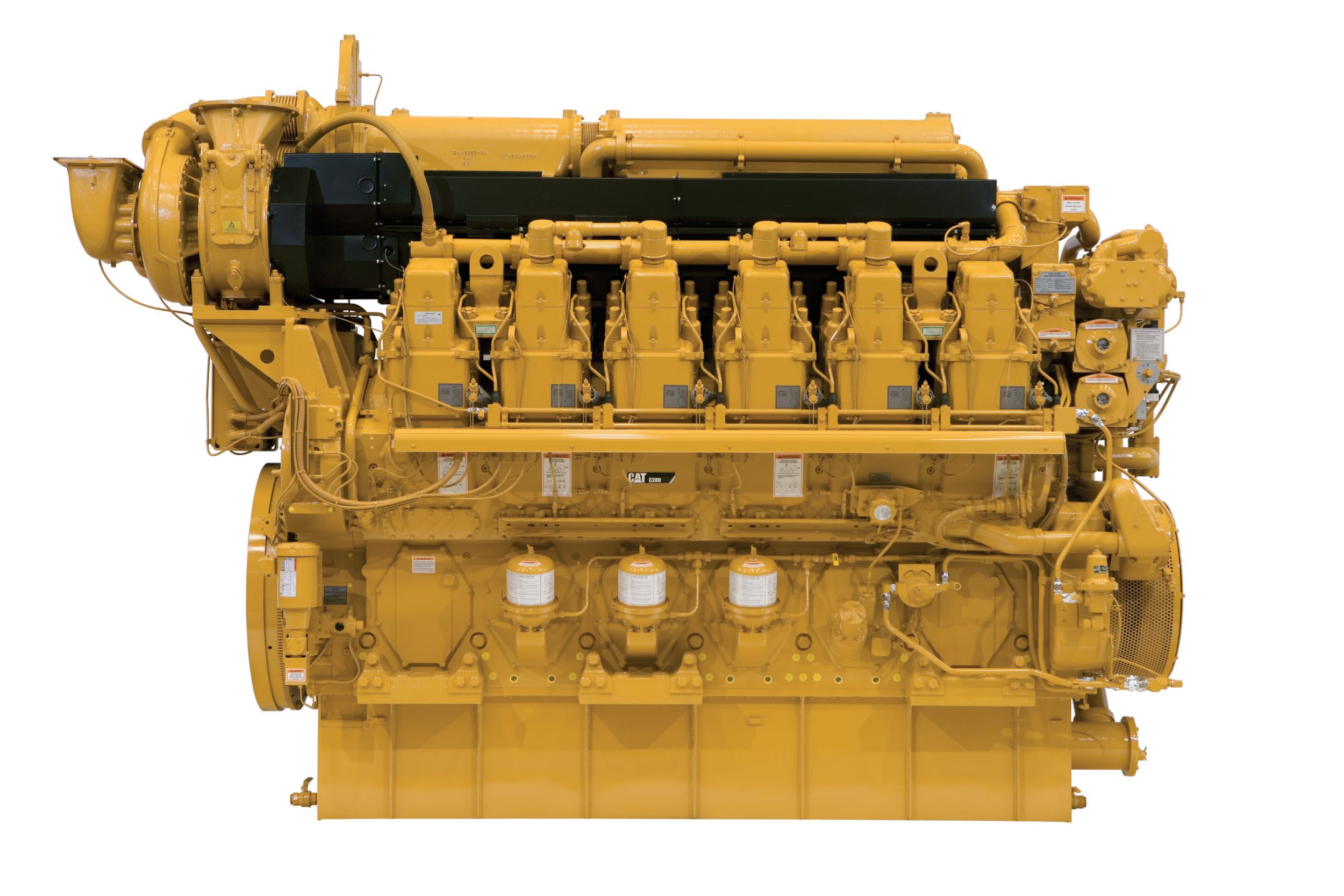

View model catalogBuilding on the durability and reliability of the C280 engine platform, Caterpillar is pleased to offer the C280-12 engine line. The core components are the same as the existing C280, including the latest in EUI fuel system capabilities and state-of-the-art ADEM™ A3 Electronic Control Unit (ECU) features. Caterpillar® products continue to deliver more available power while delivering outstanding fuel efficiency. You can also count on long maintenance intervals and worldwide Caterpillar parts and service availability.All C280-12 engines ratings are IMO II compliant. Engines rated at 3700 bkW and 4060 bkW, with aftertreatment, are IMO 3/EPA T4 compliant.

|

|

|

|

|

|

|

|

Power Rating

- Power Range

- 4,640-5,444 bhp (3,460-4,060 bkW)

Engine Specifications

- Speed Range

- 900-1,000 rpm

- Emissions

- IMO II, IMO III/EPA T4

- Aspiration

- TTA

- Bore

- 11 in

- Stroke

- 11.8 in

- Displacement

- 13,546 in³

- Rotation from Flywheel End

- Counterclockwise or clockwise

- Configuration

- Vee 12, 4-Stroke-Cycle Diesel

Dimensions & Weights

- Minimum Dry Weight

- 57,276 lb

- Minimum Length

- 182 in

- Maximum Length

- 182 in

- Minimum Height

- 134 in

- Maximum Height

- 134 in

- Minimum Width

- 80 in

- Maximum Width

- 80 in

Specifications

Power Rating

- Power Range

- 4,640-5,444 bhp (3,460-4,060 bkW)

Engine Specifications

- Speed Range

- 900-1,000 rpm

- Emissions

- IMO II, IMO III/EPA T4

- Aspiration

- TTA

- Bore

- 11 in

- Stroke

- 11.8 in

- Displacement

- 13,546 in³

- Rotation from Flywheel End

- Counterclockwise or clockwise

- Configuration

- Vee 12, 4-Stroke-Cycle Diesel

Dimensions & Weights

- Minimum Dry Weight

- 57,276 lb

- Minimum Length

- 182 in

- Maximum Length

- 182 in

- Minimum Height

- 134 in

- Maximum Height

- 134 in

- Minimum Width

- 80 in

- Maximum Width

- 80 in

Standard/Optional Features

Standard Equipment:

-

- General

-

- LH and RH service availability

-

- Air Inlet System

-

- Aftercooler, fresh water, corrosion resistant coated (air side)

- Crankcase breathers, top mounted

- Dual turbochargers, rear-mounted, engine oil lubricated

-

- Control System

-

- Dual Caterpillar ADEM A4 Electronic Engine Control Modules

- Rigid Wiring Harness

-

- Cooling System

-

- Aftercooler / oil cooler and jacket water pumps (gear driven)

- Engine coolant water drains

- Single Circuit / Separate Circuit Aftercooler

-

- Exhaust System

-

- Dry, gas tight, exhaust manifold

- Turbo speed sensors - Overspeed protection

-

- Fuel System

-

- Fuel transfer pump, gear driven

- Duplex Fuel filters

- Electronically Controlled Unit Injectors

-

- Instrumentation

-

- Cat Alarm & Protection System

-

- Lube System

-

- Oil pump, gear driven

- 3 element oil cooler, engine mounted

- Duplex centrifugal oil filter - engine mounted

- Prelube pump - air / electric

-

- Protection System

-

- Crankcase explosion relief valves

Optional Equipment:

-

- Exhaust System

-

- Exhaust manifold shielding - soft

-

- Lube System

-

- Front and rear oil pan drains

- Wet Sump

- SOLAS shielding

-

- Protection System

-

- Oil mist detector

- Cylinder pressure relief valves

-

- Fuel System

-

- SOLAS shielding