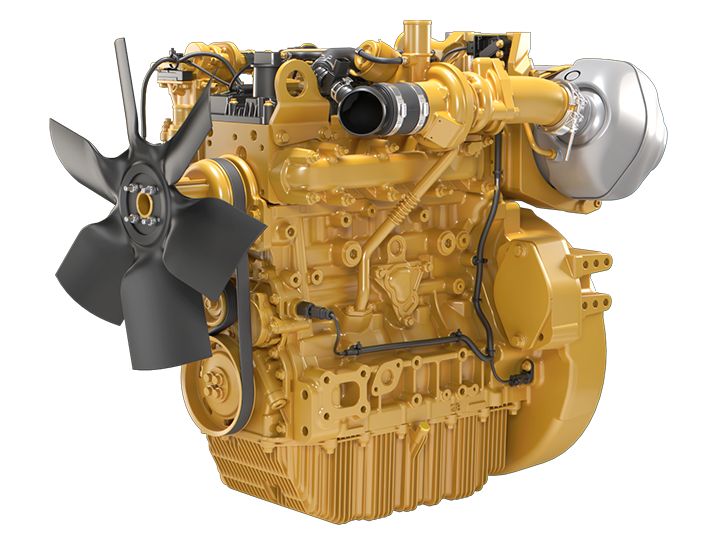

The Cat® C2.8 Industrial Diesel Engines offer the perfect balance of compact size, reliability, and performance. This engine is offered in ratings ranging up to 55 bkW (74 bhp) @ 2500 rpm. The C2.8 is designed to meet the needs of many industries and applications, including agricultural tractors, aerial lifts, aircraft ground support, bore/drill rigs, chippers/grinders, compactors/rollers, compressors, forestry, irrigation equipment, material handling, mining, earthmoving equipment, paving equipment, pumps, fruit harvesters equipment, turf and underground mining equipment.

|

|

|

|

|

|

|

|

Power Rating

- Maximum Power

- 74 hp

- Maximum Torque

- 280 lb-ft @ 1360 rpm

- Rated Speed

- 2,200 - 2,400 rpm

- Minimum Power

- 67 hp

Emission Standards

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

General

- Engine Configuration

- In-Line 4

- Bore

- 3.5 in

- Stroke

- 4.3 in

- Displacement

- 171 in³

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged (T) and Turbocharged-Aftercooled (TA)

- Combustion System

- Direct Injection

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- DOC+DPF

Engine Dimensions - Approximate

- Length

- 24.9 in

- Width

- 22.4 in

- Height

- 30.9 in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 750 lb

Specifications

Power Rating

- Maximum Power

- 74 hp

- Maximum Torque

- 280 lb-ft @ 1360 rpm

- Rated Speed

- 2,200 - 2,400 rpm

- Minimum Power

- 67 hp

Emission Standards

- Emissions

- U.S. EPA & CARB Tier 4 Final, EU Stage V

General

- Engine Configuration

- In-Line 4

- Bore

- 3.5 in

- Stroke

- 4.3 in

- Displacement

- 171 in³

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged (T) and Turbocharged-Aftercooled (TA)

- Combustion System

- Direct Injection

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- DOC+DPF

Engine Dimensions - Approximate

- Length

- 24.9 in

- Width

- 22.4 in

- Height

- 30.9 in

- Weight - Net Dry - Basic Operating Engine Without Optional Attachments

- 750 lb

Standard/Optional Features

Standard Equipment:

-

- Air Inlet System

-

- Induction manifolds

- Exhaust manifolds

- Engine-mounted aftertreatment

-

- Control System

-

- Starter motor (12V)

- Alternator (12V)

- Electronic Control Unit (chassis mounted)

- Engine control sensors and robust wiring harness

- Data interface via CANbus J1939

-

- Flywheels And Flywheel Housing

-

- Flywheel housings – SAE 3 or SAE 4

- Choice of flywheel to match industry common hydraulic pumps and transmissions

- Side PTO with SAE A or SAE B interface

-

- Fuel System

-

- Fuel filter – preconnected but chassis mounted

- With water sensor

-

- Lube System

-

- Lubricating oil filters

- High incline oil pan – 35° continuous in all directions

-

- General

-

- Cold start capability to -20° C (-4° F) with standard equipment

- Paint: Caterpillar yellow, with optional colors available at request

-

- U.s. Epa Tier 4 Final, Proposed Eu Stage V Aftertreatment/ Clean Emissions Control Equipment

-

- Diesel Oxidation Catalyst (DOC) (Tier 4 Final and Stage V)

- Diesel Particulate Filter (DPF) (Stage V)

Optional Equipment: