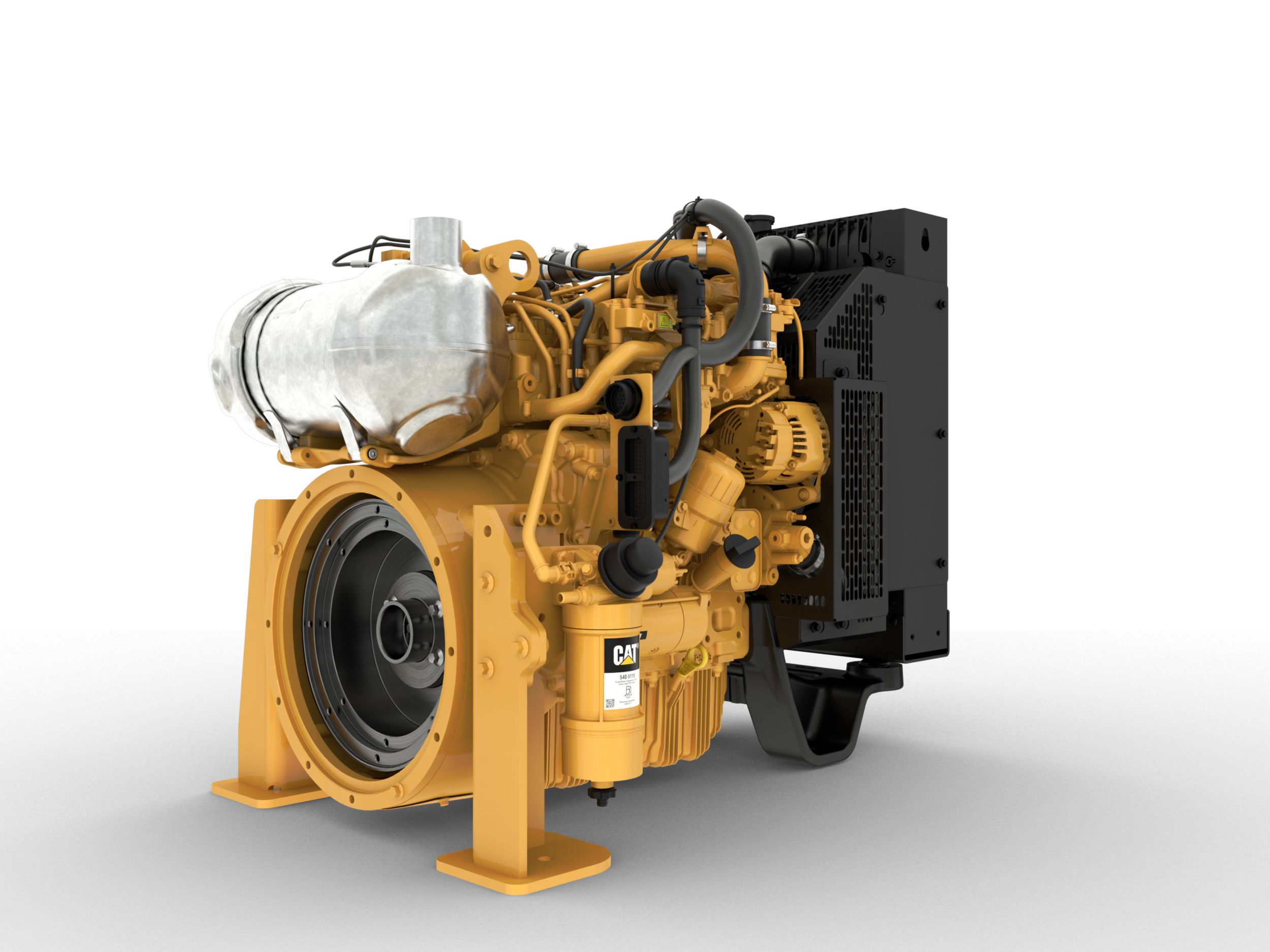

The C2.8 and C3.6 IPU engines are common rail direct injection engines with a turbocharged or turbocharged aftercooled air system meeting EU Stage V, U.S. EPA Tier 4 Final and Japan 2014 (Tier 4 Final) emission standards. For ease of installation, the IPU provides full aftertreatment mounting, an integrated cooling system, a full wiring harness and mounting for the ECM and fuel filter.

Designed to meet EU Stage V/U.S. EPA Tier 4 Final/ Japan 2014 (Tier 4 Final) emission standards.

|

|

|

|

|

|

|

|

Power Rating

- Maximum Power

- 74 HP

- Maximum Torque

- 221 lb-ft @ 1600 rpm

- Rated Speed

- 2,200-2,400 rpm

- Minimum Power

- 74 HP

Emission Standards

- Emissions

- EU Stage V/U.S. EPA Tier 4 Final/ Japan 2,014 (Tier 4 Final)

General

- Number of Cylinders

- 4 inline

- Cycle

- 4 stroke

- Bore

- 3.54 in

- Stroke

- 4.33 in

- Displacement

- 170.9 in³

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged

- Combustion System

- Direct injection

- Rotation from Flywheel End

- Anti-clockwise

- Aftertreatment

- DOC+DPF

- Cooling System

- Liquid

Engine Dimensions*

- Length

- 46.9 in

- Width

- 31.9 in

- Height

- 38 in

- Dry Weight

- 1,126 lb

Disclaimer

- Note 1

- *Final dimensions dependent on selected options

Standard Equipment:

-

- Aftertreatment Equipment

-

- Aftertreatment mounted on engine as standard

-

- Air System

-

- Standard and heavy duty air cleaners

-

- Cooling System

-

- 50:50 water glycol mix

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Engine mounted radiator with top tank temperature of 108°C (226°F)

- Pusher or puller fan options

- Radiator erosion screen is available

-

- Electrical And Electronics

-

- 12V system

- Data interface via CANbus J1939

- Instrument control panel available

- Full electronic control

- Glow plugs for best cold starting with minimum battery impact

- High power alternator and starter motor options

- Sensors and robust wiring harness included

-

- Flywheel And Flywheel Housing

-

- SAE3 flywheel housing and flywheel with pilot bore

- Wide choice of interfaces for common transmissions and hydraulic pumps

-

- Fuel System

-

- Electronic high pressure common rail

- Fuel filter - IOPU mounted

- Standard and heavy duty fuel filtration

- Water sensor included - early warning for operator

-

- General

-

- Cold-start capable with standard equipment to -25°C

- Supplied painted or lacquered

-

- Oil System

-

- Oil filters - mounting options available on either side of the engine, plus remote

- Dipsticks - choice of position and length

- High incline sump. 35° continuous in all directions. Suitable for machines that are used on steep slopes

-

- Power Take-off (pto)

-

- SAE-A and SAE-B interfaces available

Optional Equipment:

Specifications

Power Rating

- Maximum Power

- 74 HP

- Maximum Torque

- 221 lb-ft @ 1600 rpm

- Rated Speed

- 2,200-2,400 rpm

- Minimum Power

- 74 HP

Emission Standards

- Emissions

- EU Stage V/U.S. EPA Tier 4 Final/ Japan 2,014 (Tier 4 Final)

General

- Number of Cylinders

- 4 inline

- Cycle

- 4 stroke

- Bore

- 3.54 in

- Stroke

- 4.33 in

- Displacement

- 170.9 in³

- Compression Ratio

- 17.0:1

- Aspiration

- Turbocharged

- Combustion System

- Direct injection

- Rotation from Flywheel End

- Anti-clockwise

- Aftertreatment

- DOC+DPF

- Cooling System

- Liquid

Engine Dimensions*

- Length

- 46.9 in

- Width

- 31.9 in

- Height

- 38 in

- Dry Weight

- 1,126 lb

Disclaimer

- Note 1

- *Final dimensions dependent on selected options

Standard/Optional Features

Standard Equipment:

-

- Aftertreatment Equipment

-

- Aftertreatment mounted on engine as standard

-

- Air System

-

- Standard and heavy duty air cleaners

-

- Cooling System

-

- 50:50 water glycol mix

- Detailed guidance on cooling system design and validation available to ensure machine reliability

- Engine mounted radiator with top tank temperature of 108°C (226°F)

- Pusher or puller fan options

- Radiator erosion screen is available

-

- Electrical And Electronics

-

- 12V system

- Data interface via CANbus J1939

- Instrument control panel available

- Full electronic control

- Glow plugs for best cold starting with minimum battery impact

- High power alternator and starter motor options

- Sensors and robust wiring harness included

-

- Flywheel And Flywheel Housing

-

- SAE3 flywheel housing and flywheel with pilot bore

- Wide choice of interfaces for common transmissions and hydraulic pumps

-

- Fuel System

-

- Electronic high pressure common rail

- Fuel filter - IOPU mounted

- Standard and heavy duty fuel filtration

- Water sensor included - early warning for operator

-

- General

-

- Cold-start capable with standard equipment to -25°C

- Supplied painted or lacquered

-

- Oil System

-

- Oil filters - mounting options available on either side of the engine, plus remote

- Dipsticks - choice of position and length

- High incline sump. 35° continuous in all directions. Suitable for machines that are used on steep slopes

-

- Power Take-off (pto)

-

- SAE-A and SAE-B interfaces available

Optional Equipment: